Engineered for Greener Highways

REBLOC LC RB80 XA H1 W1 is Hardstaff’s Low Carbon variant of the existing RB80 XA line, cutting CO2 emissions by half compared to the standard products.

This has been achieved through an ambitious value engineering programme in collaboration with our supply chain, starting with our precast H2 containment Rigid Concrete Barrier (RCB), RB 80XA. The new model RB80 XA H1 W1, an addition to our range, maintains the same profile as our existing products whilst requiring significantly less steel and concrete to produce. Combined with the use of a low carbon concrete mix, developed specifically for Hardstaff, we’ve drastically cut the carbon emissions in manufacturing REBLOC H1 LC.

Crash tested to meet EN1317 standards, it is the new benchmark precast concrete barrier supporting lean construction programmes in the market.

Contact Us

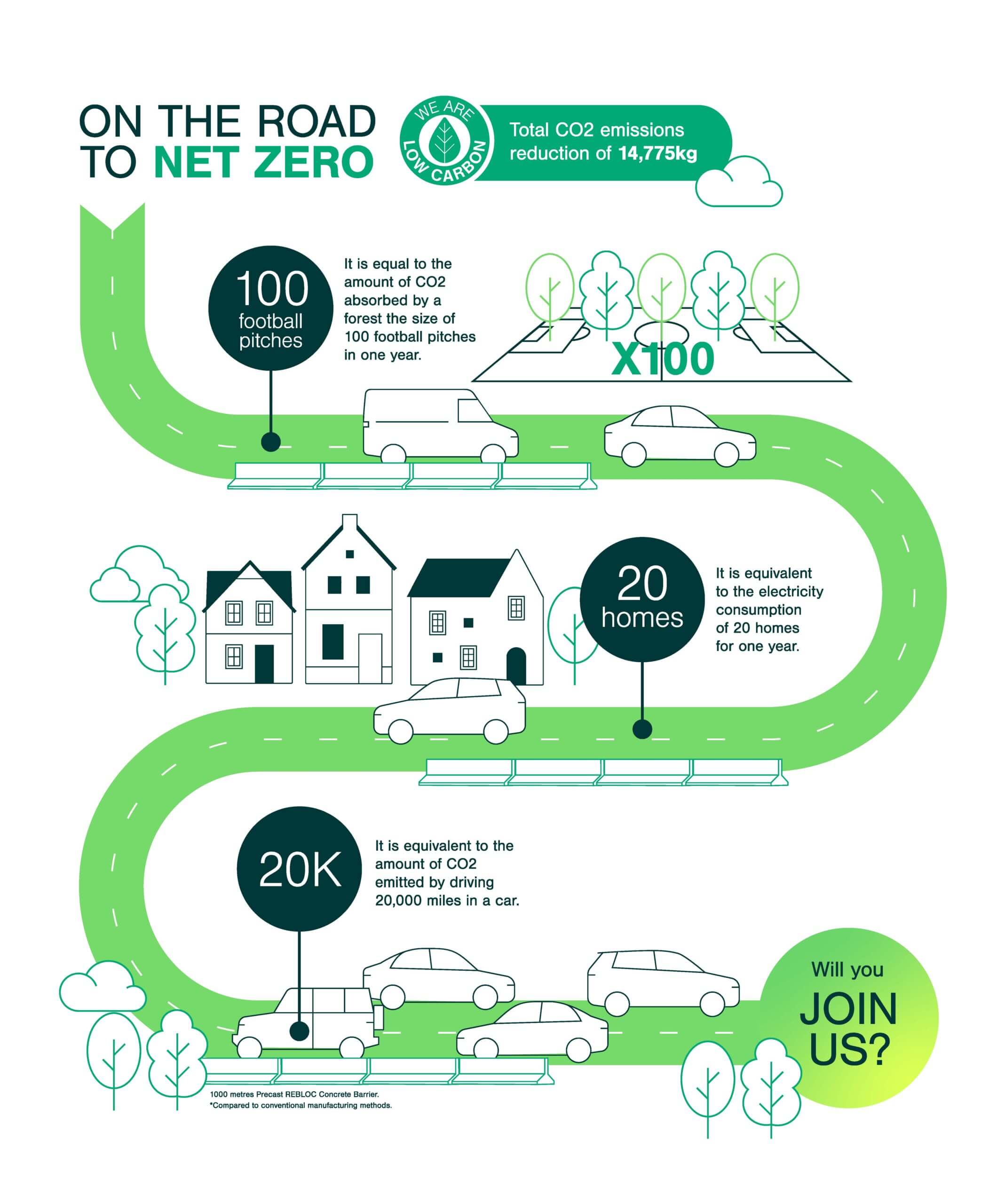

Carbon Savings

Leaner construction programmes are now easier to achieve than ever with our reduced carbon emissions concrete barrier. With 20% less concrete, 50% less steel, and 33% fewer emissions through the use of low carbon concrete, our precast concrete barrier is setting a new standard, halving carbon emissions compared to conventional production methods. To understand the positive impact of innovative value-engineering, let’s explore the carbon savings for a 1,000m barrier production.

Low Carbon Concrete

Utilising a bespoke low carbon concrete mix developed exclusively for Hardstaff Barriers, we’re implementing more sustainable construction across our entire concrete barrier product range, including Multibloc (V28 TVCB), Maxibloc (V50 THVCB), and all REBLOC offerings. This innovation enables us to achieve a significant 33% reduction in carbon emissions, not only increasing the eco-efficiency of our barriers but also furthering Hardstaff’s commitment to a Net Zero future.

Free VRS & Passive Safety Presentation

Take advantage of decades of experience in developing,

manufacturing, installing and maintaining a broad range of

highways products, presented to you by established and

informed experts in the roads sector.

- Understand highway standards for the use of VRS

and best value design. - Learn about new solutions that provide increased

efficiencies and support carbon reduction. - A live presentation, allowing for Q&A throughout the

presentation.